What It Does and the Key Benefits It Offers

We create custom machine-learning models to optimize industrial processes in real time.

Reduce energy consumption and CO2 emissions

Improve product quality

Minimize raw material costs

Integrate easily into existing data infrastructure

Case Studies

EAF – Energy Consumption Reduction

Metalfer, Serbia

Predicting energy consumption using ~40 process parameters → led to energy savings.

Finished project

EAF – Raw Materials Savings

Metalfer, Serbia

ML method to reduce alloying elements (Mn, Si) by changing process practice.

Finished project

EAF – Mechanical Properties

Metalfer, Serbia

Impact of tramp elements on tensile strength to tune process parameters.

Ongoing

EAF – Lime and Carbon Injection

Metalfer, Serbia

Optimizing slag foaming with an ML model and new injection equipment.

Ongoing

Energy Revision – HBIS, Serbia

(by University of Belgrade, Faculty of Technology and Metallurgy)

Monitoring energy consumption in multiple processing units to find leaks and savings.

Finished

Material Savings via Microalloying

HBIS, Serbia

Predicting mechanical properties by replacing large amounts of Mn with microelements.

Ongoing

Natural Gas Combustion Optimization

Reducing carbon and NOx emissions in local heating plants.

Ongoing, seeking local partner

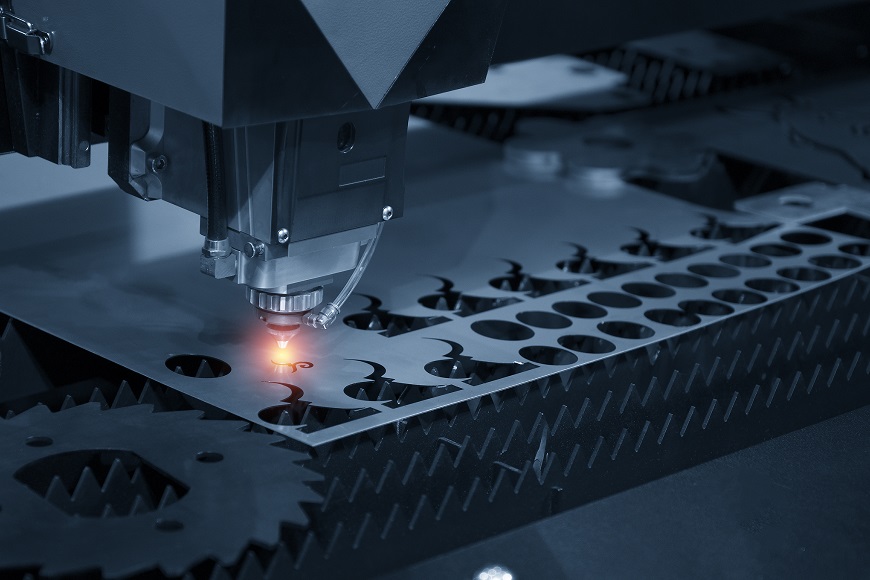

Welding Error Detection

Kontrolinspect, Serbia

ML-based classification of weld defects using historical XRD images.

Ongoing

.jpg)

Alloy Development (Ti Alloys)

Designing new biocompatible/aerospace titanium alloys by combining first-principles calculations, ML, and experimental data.

Ongoing, seeking partners

Methods & Technologies

Data-Driven Machine Learning Approach

Outline your step-by-step method (data collection, cleaning, model building, real-time monitoring).

Real-Time Process Monitoring

Short paragraph describing how you integrate sensors, data acquisition, and model updates.

Expert Knowledge

o Emphasize the importance of domain expertise (metallurgy, process engineering) combined with data science.

Contact Us for a Consultation

References & Partners

Selected Publications

V. Manojlović et al. “Machine learning analysis of electric arc furnace process...,” Applied Energy, 307 (2022).

Industry Partners

Metalfer, HBIS, Kontrolinspect, University of Belgrade (Faculty of Technology and Metallurgy)